Sig P322 Suppressor, 3D Printed

I was inspired by The SilencerCo Maxim 9 (Not imported in France) to design my own suppressor following a similar philosophy : maximizing the suppressor volume with a very specific design.

Disclaimer : Suppressors are perfectly legal and non-regulated items in France.

If you use any part of this post to produce a suppressor in the USA - or any country where this is illegal, you are sole responsible for any legal consequences.

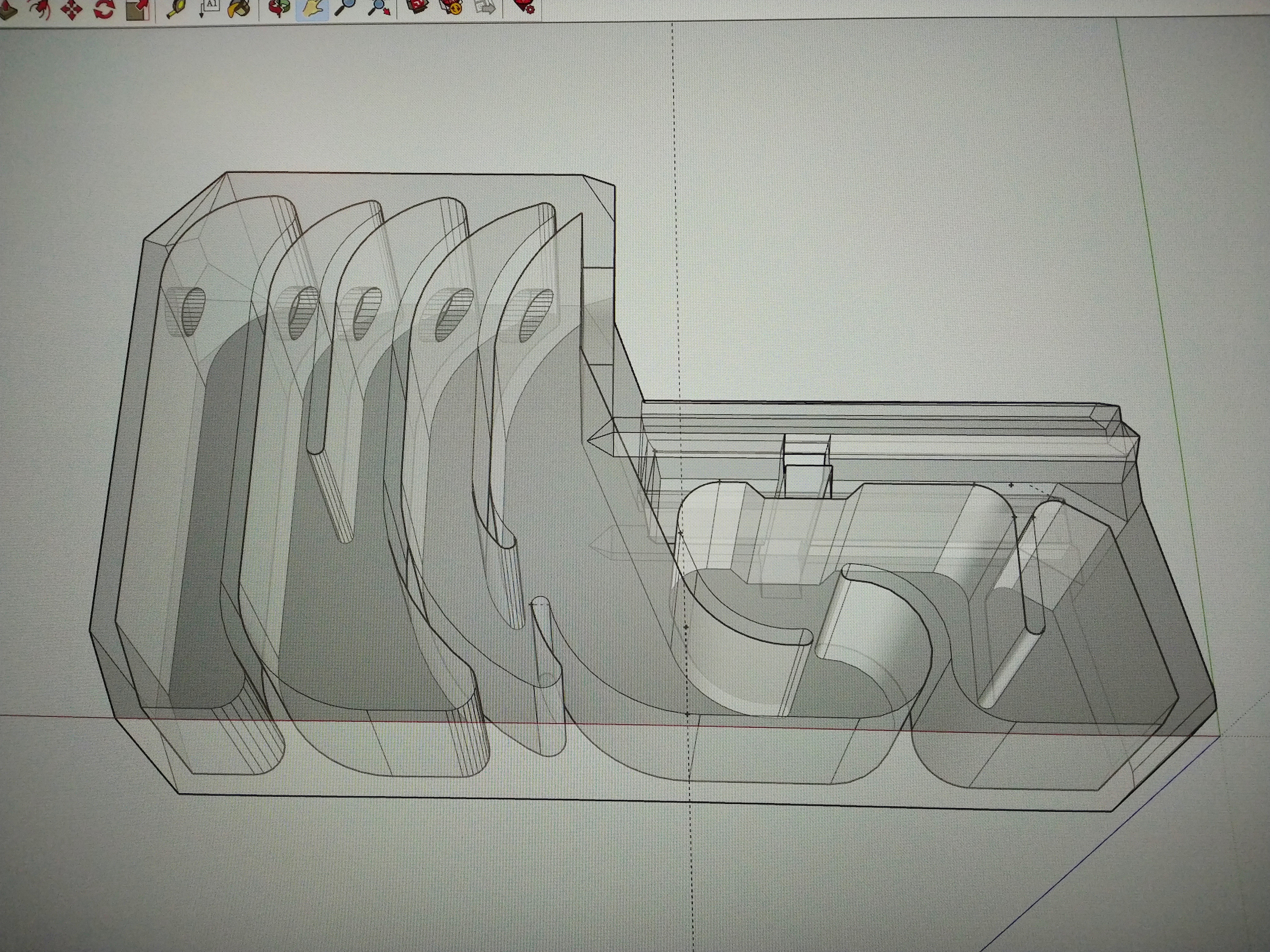

Drawing was done using Sketchup (a fairly old version).

As I don't have access to a metal additive manufacturing machine and the shape is too complex for manual machining, my materials choices were restricted to plastics.

Ideal choice would have been Nylon (PA6) or Polycarbonate (PC), but I used ABS as it is much easier to print and allows for some interesting post-processing as you will see.

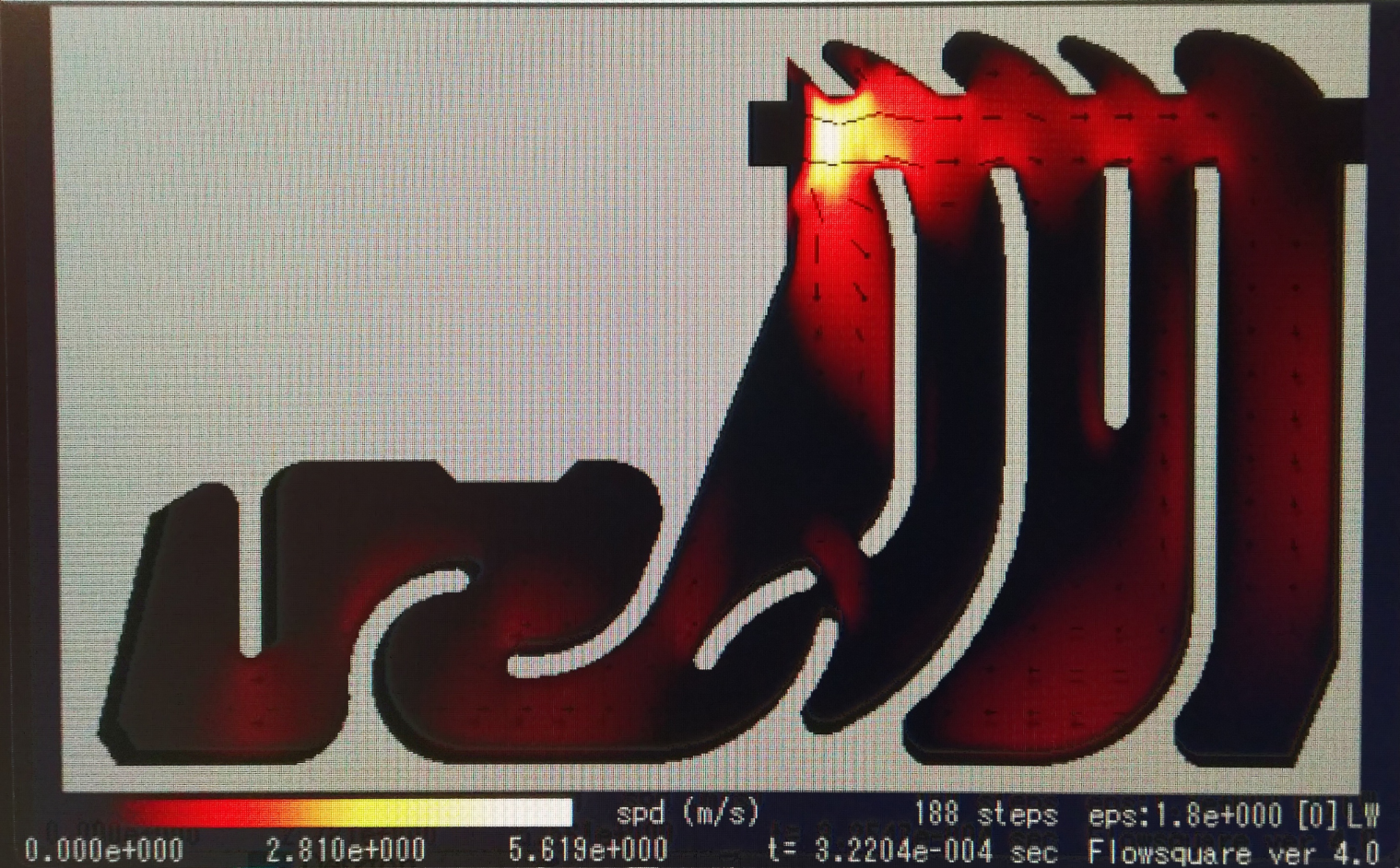

I did some FEA / flow modeling but my limited experience and lack of access to pro software limited the outcome.

I also went thru a few prototypes

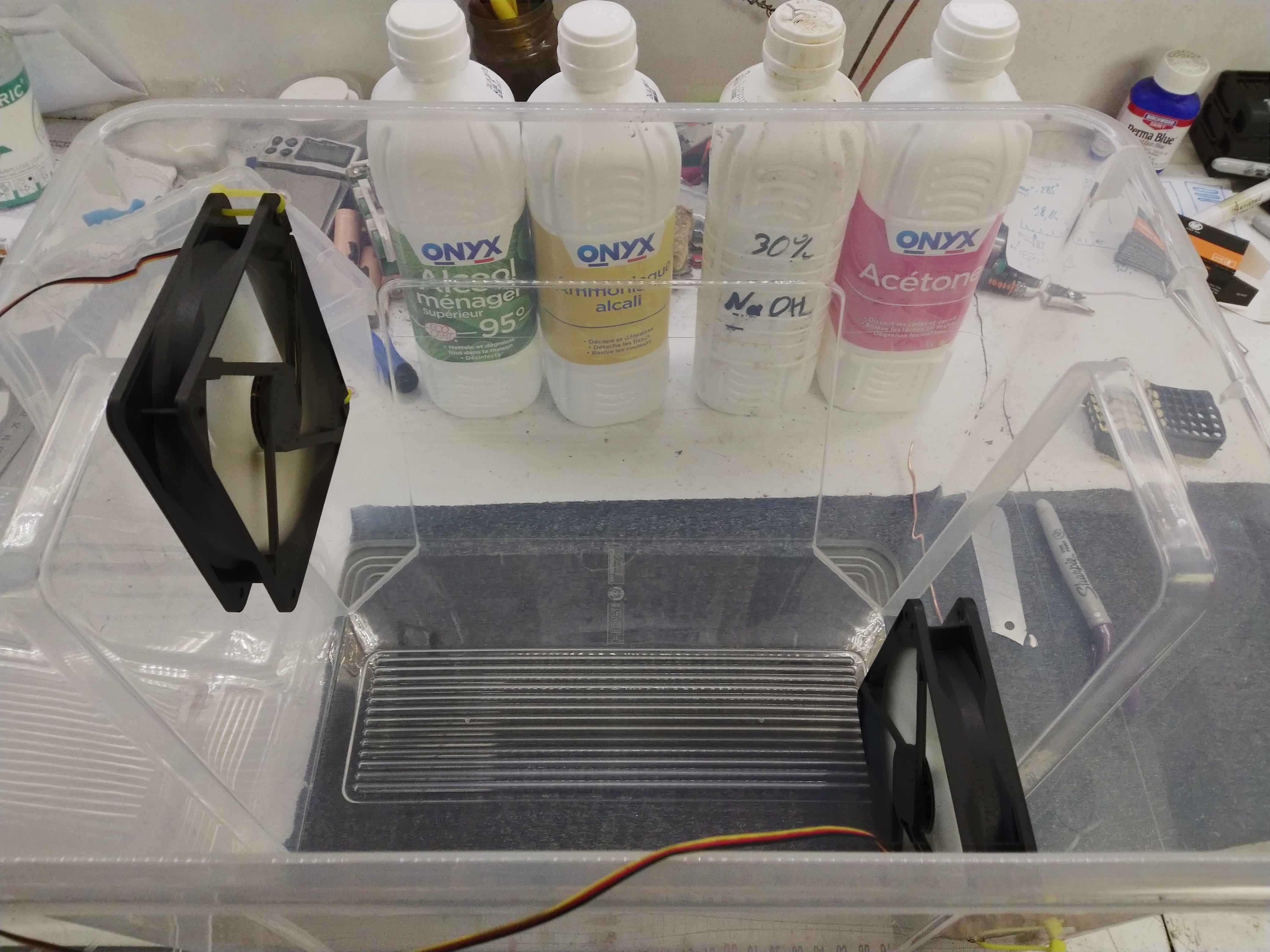

I blew a few. In the picture above, the last one has acetone vapor bubbles. The one next to it and lacking its bottom part blew apart (it had not been acetone treated).

There was some fine fitment refining but the final iteration slides on the Picatinny rail with just the right amount of force.

I used a dual nozzle printer, so that internal support could use PLA instead of ABS. The supports are destroyed during the first firing of the suppressor. Although my initial goal was to dissolve PLA using Isopropyl alcohol, which supposedly could dissolve PLA without touching ABS. It ended up doing nothing to either.

After printing, the suppressor is put in an Acetone vapor chamber until the Acetone penetrated the ABS enough to perfectly bound the layers. After that it is let to dry out. Once dry, it is sand blaster to remove the shiny finish.

The result is impressively quiet and durable.

I should provide the 3D model on this blog shortly.