Sizing of my heat pump (Daikin 3MXM52)

Summer 2023, I finaly decided to equip our house with a heat pump. When we first renovated it in 2016, this didn't fit in our budget but I always dreamt of having a heat pump (who doesn't?).

Bellow are my calculation and considerations. Plus some conclusions and retrospective data once the installation was completed.

The building

It is a 3 story house built in 1947, all joined by open stairwells without doors.

The first level is partially underground. It has been renovated to French standard RT2012 in 2016. If you aren't unfamiliar with this norm, it requires roughly 18cm of glass wool in the walls, and 25cm in the roof plus fairly serious efforts to make the building airtight. In addition, I used

- Triple glazing non-opening windows on all North side (PVC structure), and double glazing otherwise.

- Dual flow ventillation.

- Thermal solar panels for the hot water tank.

Openings

- A large aluminium bay window, 3m wide on the South side.

- Veranda on the South.

- Large windows on the East side

- Large non-opening windows on the Nord side

- 2 Skylights on the East side, one South and one North.

Surfaces, volumes and existing heating system

- Ground (Level 0) : 45.4m2, 100m3

- Lobby & Stairwell 16m2, 36m3 (1500W convector)

- including lobby 14.9m2, 32.8m3

- including hallway 1m2, 2.2m3

- including stairwell 3.9m2, 1m3

- Bathroom 7m2, 15m3 (800W convector/fan heater)

- Movie/Audio room 16m2, 35m3

- Laundry room 6.4m2, 14m3

- Lobby & Stairwell 16m2, 36m3 (1500W convector)

- Upstairs (Level 1) : 54.5m2, 155m3

- Living room 28.7m2, 76m3 (1500W convector)

- Kitchen/Dining room 24.78m2, 66m3 (1500W convector)

- WC 1.18m2, 2.5m3

- Attic (Level 2) : 26m2, 84m3

- Office 13m2, 27m3

- Kid bedroom 9m2, 16m3

- Parental bedroom 24m2, 41m3

Total volume : 339m3, of which 220m3 are actually heated. Total surface : 125.9m2 (floor surface).

Note that the attic is only heated by wasted convective heat from the level underneath

Thermal requirements approximations

As I didn't have an accurate electricity monitoring system at the time (no Home Assistant yet), I had to approximate the actual thermal power needed, and find good reference points to compare the outdoor temperature with the electrical consumption of the house.

Available measurements

The only available measurements are from Linky as communicated to EDF.

- In kW max per 30 minutes.

- In kWh per hour.

- In kWh per day.

The following parasitic aspects must be considered

- Wallbox, charging an electric vehicle: 28kWh once or twice a week (usually on the weekend).

- Dishwasher (powered partly by solar hot water)

- Washing machine (powered partly by solar hot water)

- Audio/Video system, constant consumption of 100 to 200W.

- Induction cooktops

- Solar gain through windows is very significant.

- The possible activation of the hot water tank heater can skew the measurements.

Reference points are taken between 4 and 8 AM and only if the electricity consumption seems stable, when there is no solar gain and no other equipment running except the audio/video system and heating. This represents 100% of the Joule effect consumption.

At 4 AM, the previous day's solar gain has dissipated. Heating returns to its nominal mode between 7 PM and 11 PM after a sunny day.

Measurement points were chosen by identifying the coldest days of the winter of 2022-2023. Then, additional temperatures were selected in increments of about 2°C, if possible on different weeks.

We can clearly see the sun's input starting at 11AM and fading by 7PM

The table below indicates the maximum power reached over 30 minutes by date and time, as well as the cumulative consumption over 24 hours. It should be noted that the average day temperature is often slightly higher than the one seen at maximum power.

| Date | Time | Temperature (°C) | Instantaneous Power (W) | Energy over 24h (kWh) | Average Power (kW) |

|---|---|---|---|---|---|

| 22/01/23 | 7AM | -2 | 2200 | 52 | 2.16 |

| 21/01/23 | 6AM | -2 | 1900 | 40 | 1.7 |

| 09/02/23 | 8AM | -1 | 2000 | 27 | 1.15 |

| 28/02/23 | 7AM | -1 | 1800 | 29 | 1.2 |

| 15/02/23 | 6AM | 2 | 1600 | 21 | 0.9 |

| 16/01/23 | 5AM | 4 | 1350 | 25 | 1 |

| 31/01/23 | 5AM | 7 | 1000 | 22 | 0.9 |

| 03/02/23 | 5AM | 8 | 900 | 28 | 1.1 |

| 18/02/23 | 7AM | 10 | 700 | 25 | 1 |

| 14/01/23 | 5AM | 12 | 500 | 16 | 0.65 |

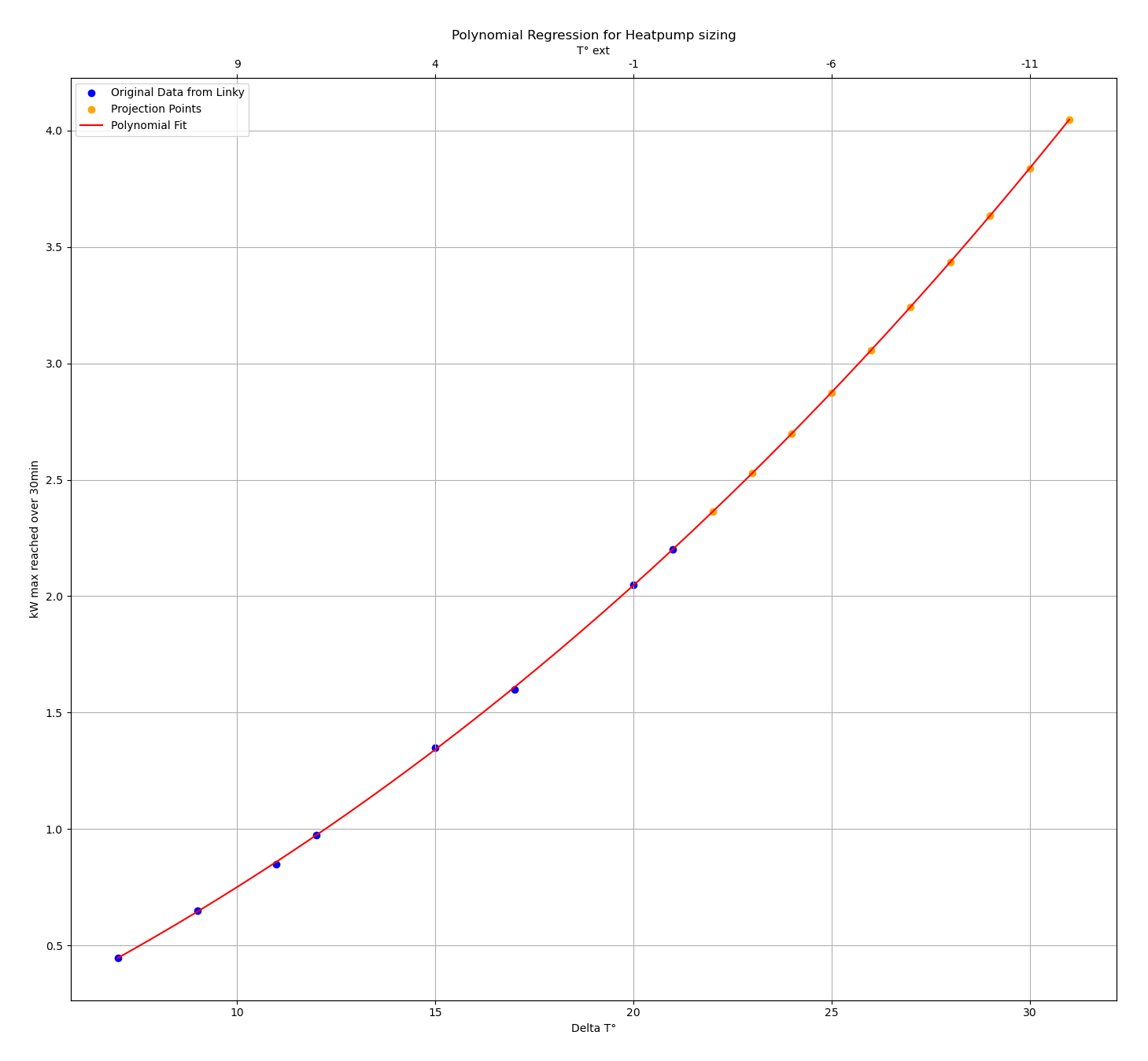

Projections of thermal requirements

In the absence of consumption measurements outside of the winter of 2022-2023 (which was very mild, with a brief minimum at -2°C), a polynomial regression is performed based on the available measurements.

The regression is performed for an indoor temperature of 19°C. This results in:

a = 0.002246, b = 0.062353, c = -0.099360

From this, we can deduce the following assumed consumptions:

| Outside T° | Inside T° | Delta T° | Thermal kW |

|---|---|---|---|

| 12 | 20.5 | 8.5 | 0.6 |

| 10 | 20.5 | 10.5 | 0.8 |

| 8 | 20.5 | 12.5 | 1 |

| 6 | 20.5 | 14.5 | 1.23 |

| 4 | 20.5 | 16.5 | 1.55 |

| 2 | 20.5 | 18.5 | 1.8 |

| 0 | 20.5 | 20.5 | 2.1 |

| -2 | 20.5 | 22.5 | 2.45 |

| -4 | 20.5 | 24.5 | 2.8 |

| -6 | 20.5 | 26.5 | 3.15 |

| -8 | 20.5 | 28.5 | 3.5 |

| -10 | 20.5 | 30.5 | 3.9 |

It should be noted that the audio/video bay of the building consumes approximately 200W, dissipated by Joule effect. Therefore, in winter, there will be a constant supply of ~200W that does not need to be covered by the heat pump (PAC).

Traditional calculation

In addition to the polynomial regression method previously detailed, I also check the theoretical power calculation using the traditional formula (P = V*C*T) gives (based on RT2012 insulation and climate zone H2)

For the entire volume of the building in a monovalent system

(339) * 0.7 * (19 – (-6)) = 5.9kW

For the actually heated volumes in a monovalent system

(220) * 0.7 * (19 – (-6)) = 3.8kW

For the actually heated volumes with a bivalent system (heat pump up to -2°C)

(220) * 0.7 * (19 – (-2)) = 3.2kW

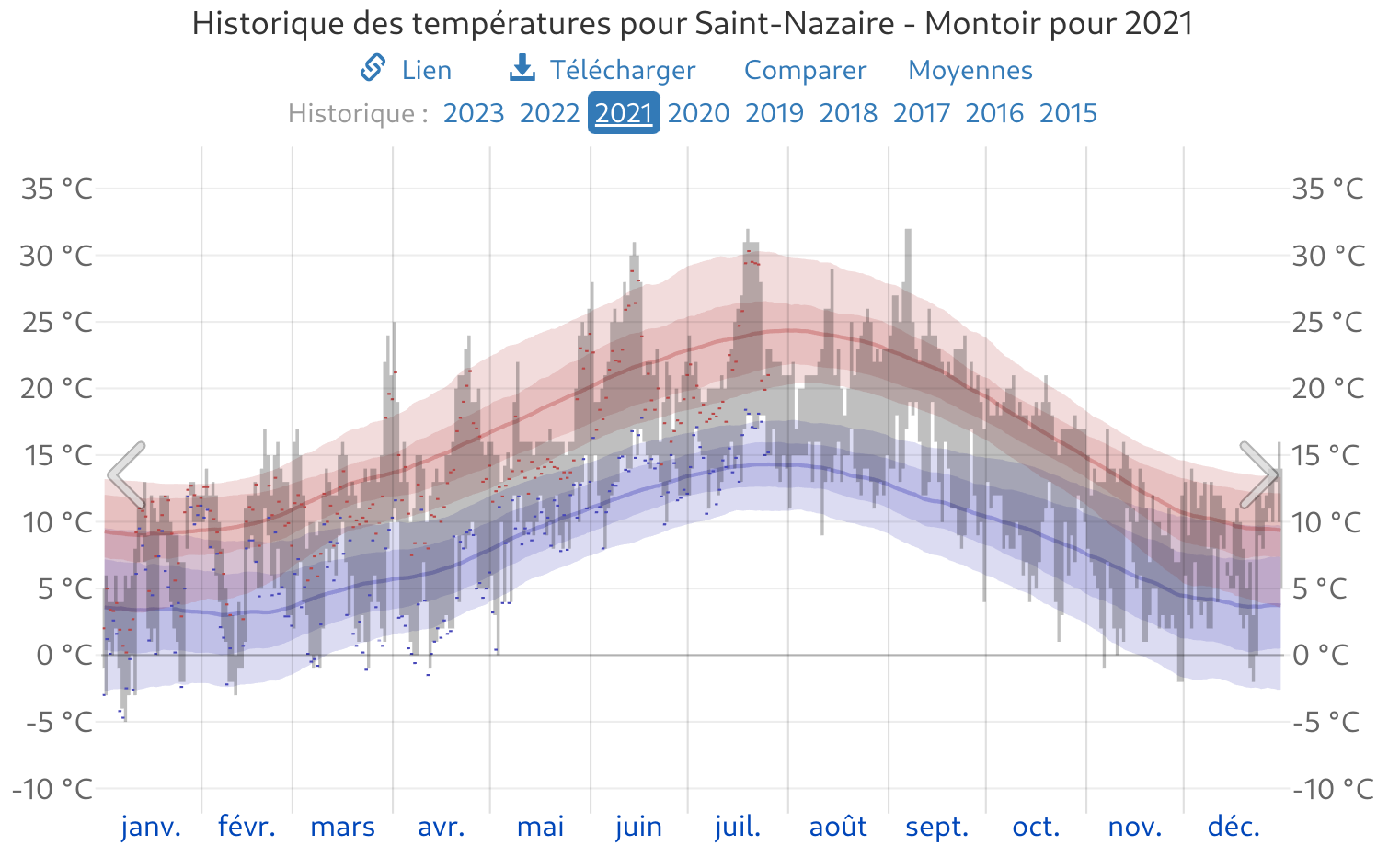

Weather Conditions

The house is located in Zone H2a (-6°C), the minimum temperatures over the last 10 years are:

| Year | -7° days | -6° days | -5° days | -4° days |

|---|---|---|---|---|

| 2013 | 0 | 0 | 1 | 0 |

| 2014 | 0 | 0 | 1 | 1 |

| 2015 | 0 | 0 | 0 | 1 |

| 2016 | 0 | 0 | 1 | 1 |

| 2017 | 0 | 2 | 5 | 6 |

| 2018 | 1 | 1 | 0 | 0 |

| 2019 | 0 | 0 | 0 | 1 |

| 2020 | 0 | 0 | 1 | 0 |

| 2021 | 0 | 0 | 1 | 2 |

| 2022 | 0 | 1 | 1 | 2 |

| 2023 | 0 | 0 | 0 | 0 |

| Total | 1 | 4 | 11 | 14 |

Since the convector installation remains in place, we can assume that the heat pump (PAC) will need to meet a minimum temperature of -5°C to -4°C.

If it satisfies:

- -5°C: Heating supplementation will be needed for 5 days over a 10-year period (0.5 days each year).

- -4°C: Heating supplementation will be needed for 16 days over a 10-year period (1.6 days each year).

- -3°C: Heating supplementation will be needed for 30 days over a 10-year period (3 days each year).

The extreme low over the last 30 years is -10°C, the average low during December-January-February is +4°C.

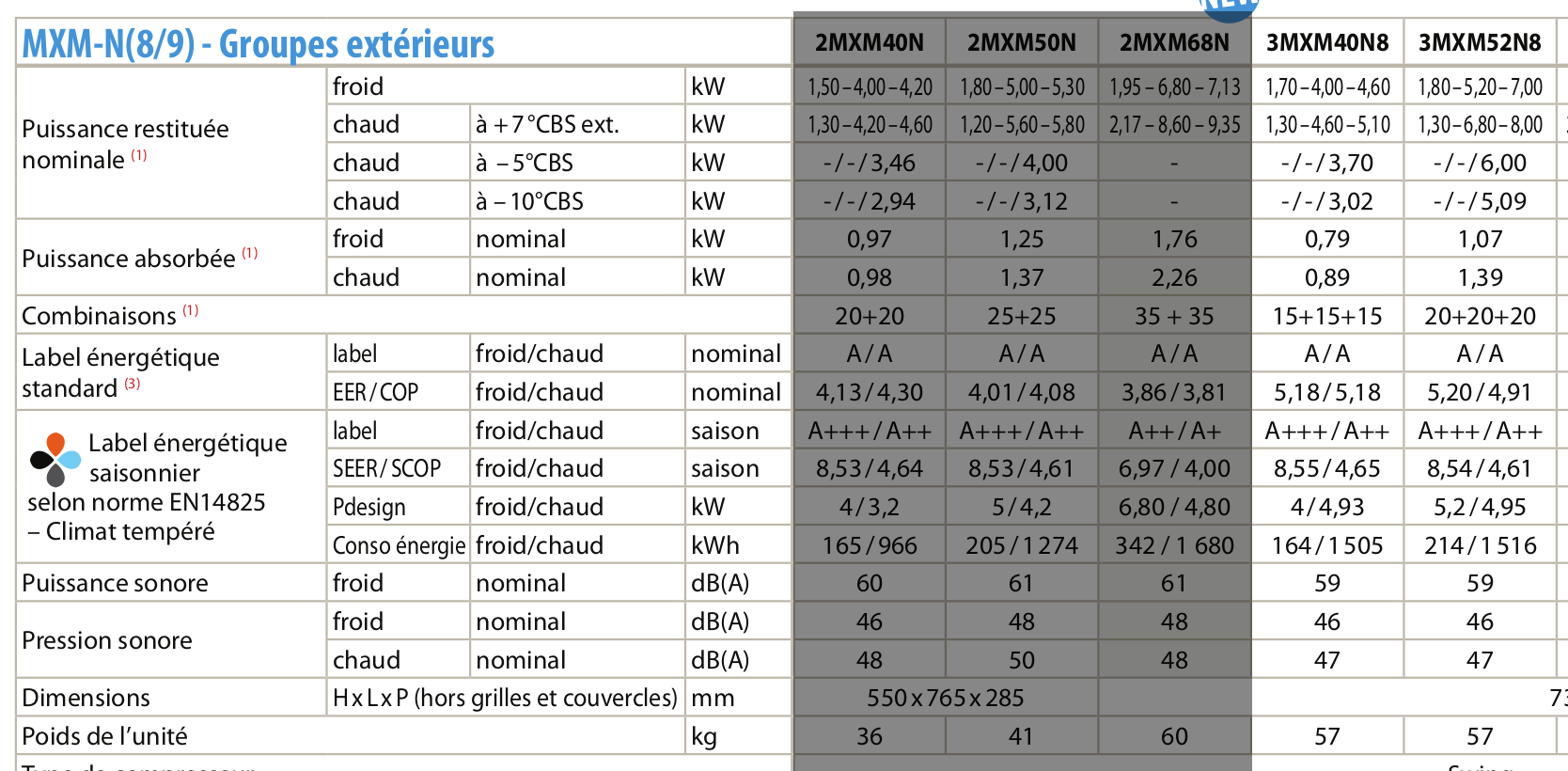

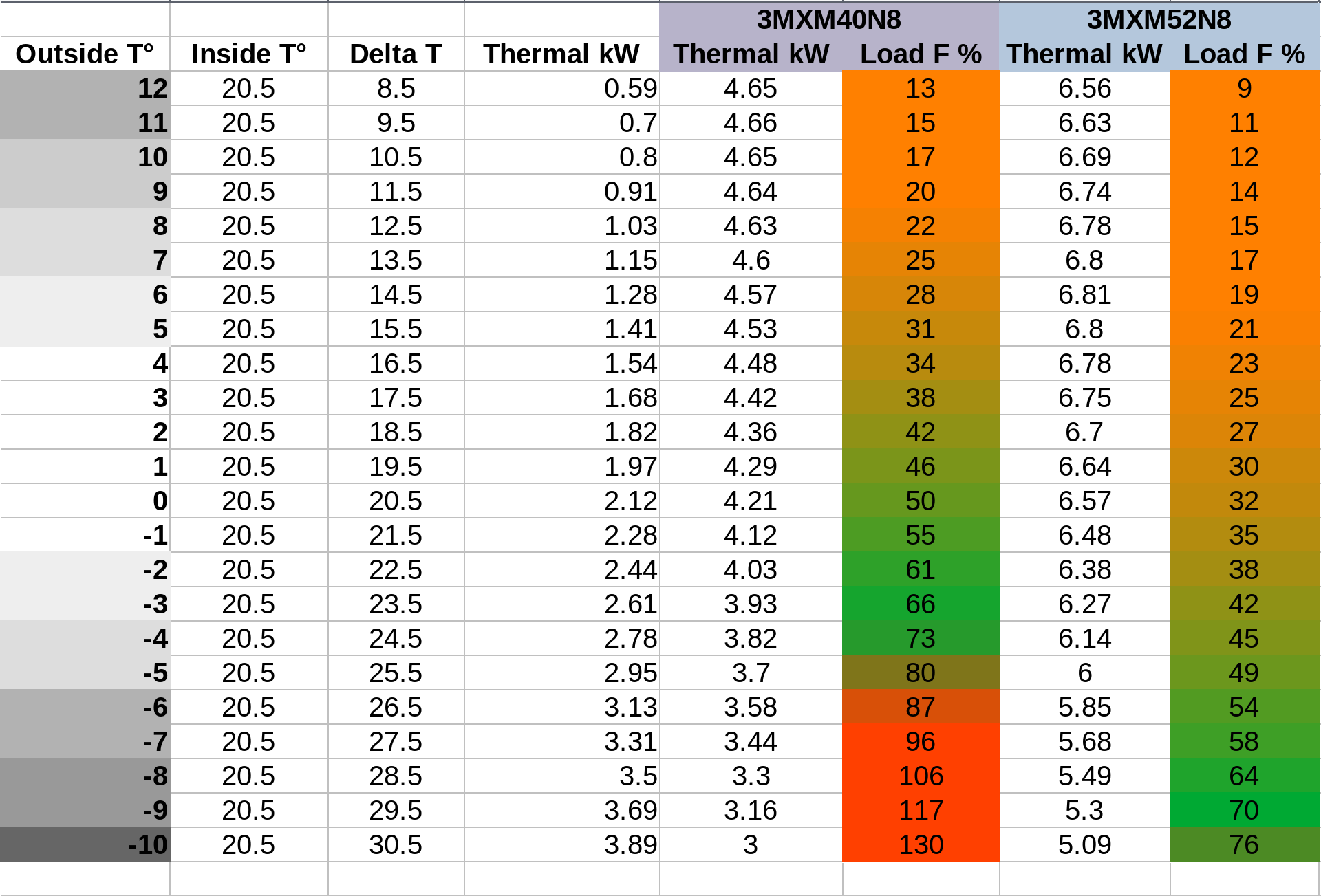

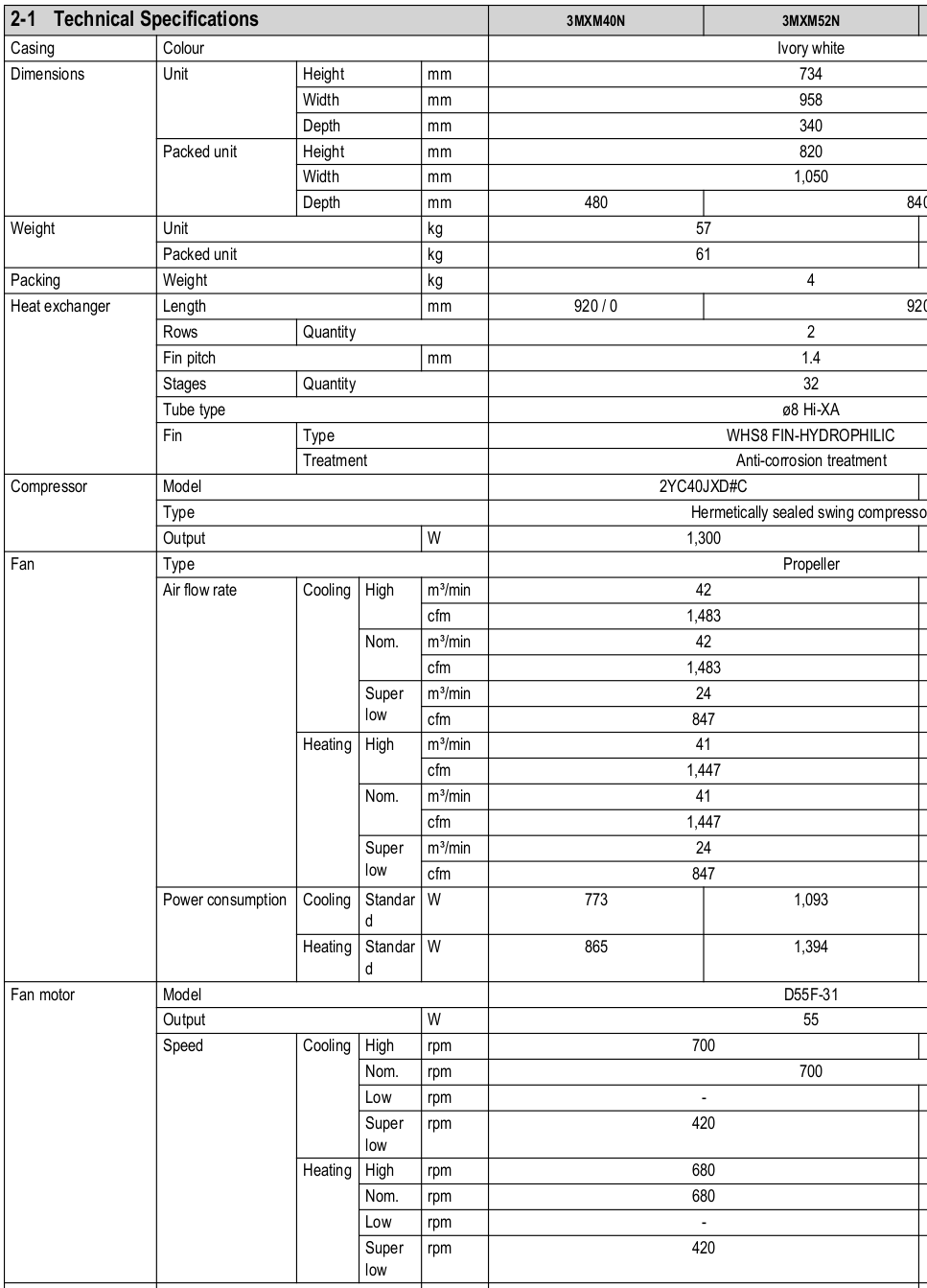

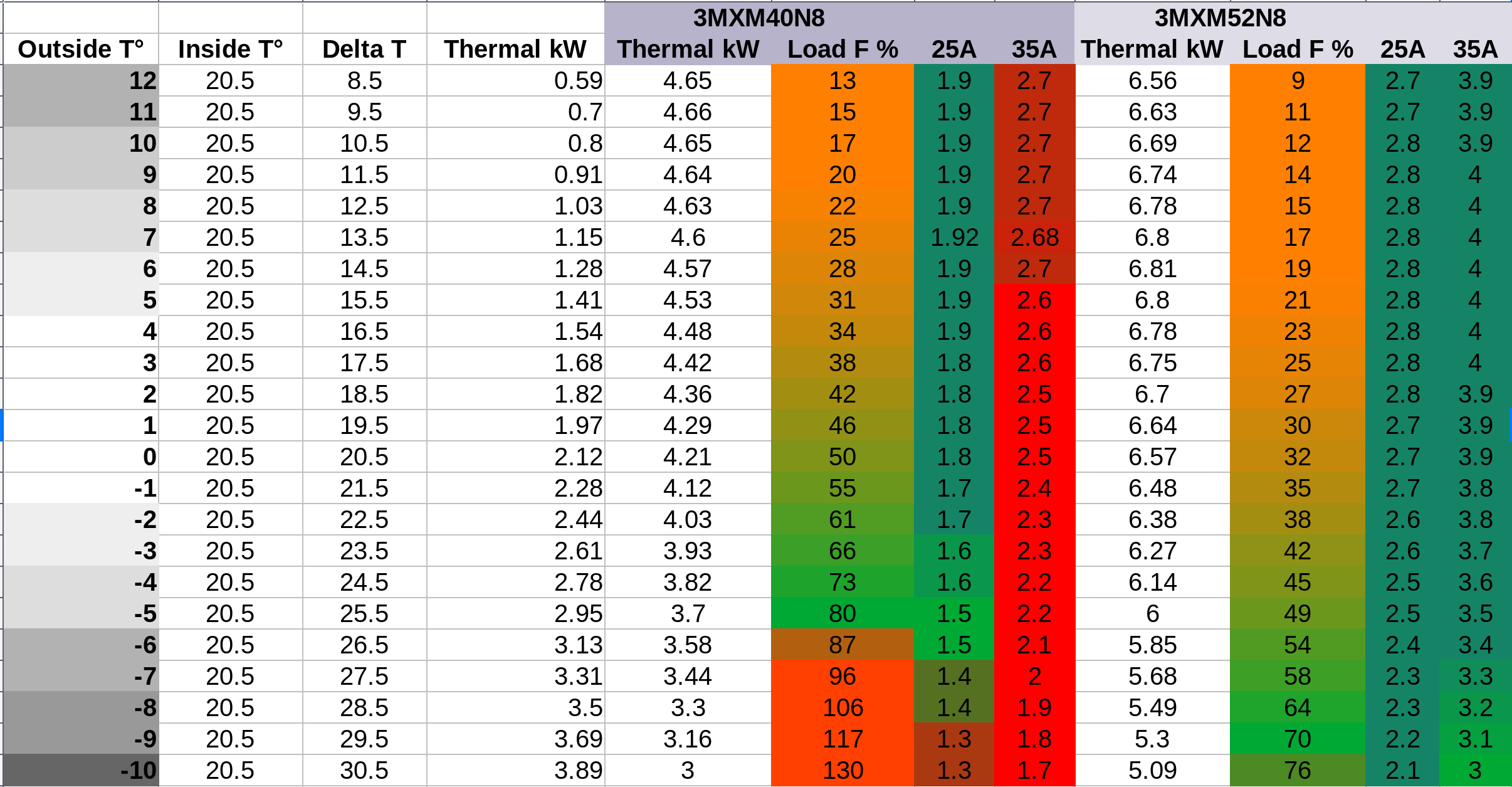

Exterior unit sizing

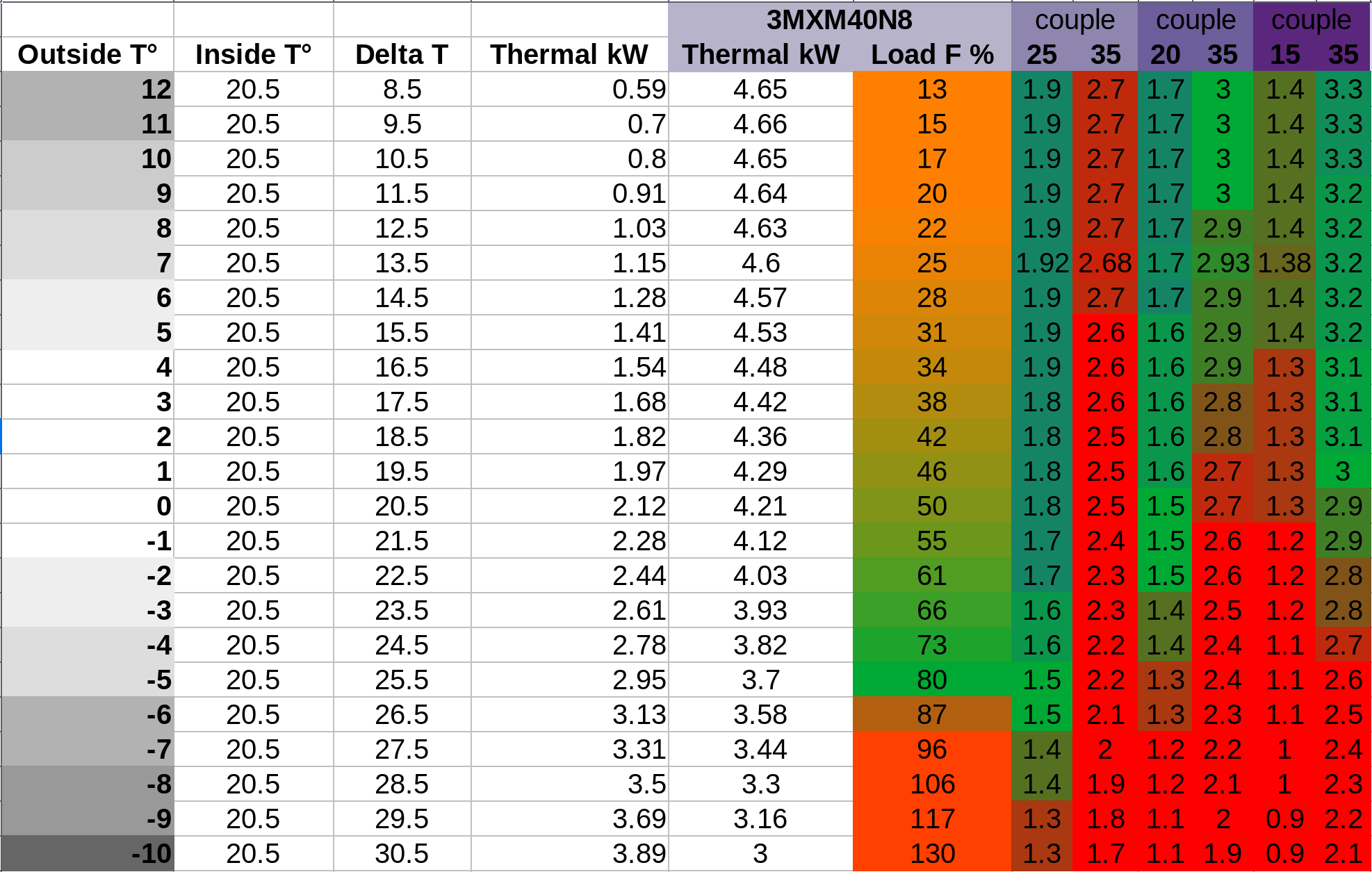

Two Daikin units are considered: 3MXM40N8 and 3MXM52N8.

- 3MXM40N8 has a heating COP of 5.18.

- 3MXM52N8 has a heating COP of 4.91.

The ideal unit should operate with a load factor fluctuating between 20% and 85%.

- 20%: To stay within the range where the inverter can vary the compressor's power without needing start-stop cycles, which wear it out prematurely.

- 85%: To allow a safety margin for the aging and progressive performance degradation over time.

The large variations in outside temperature make this ideal impossible. However, we can identify the following load factors for these two models:

- 3MXM40N8 may be at its limits at temperatures below -4°C, but its load factor is more favorable for most of its operation above this temperature.

- 3MXM52N8 is undoubtedly capable of covering all needs, but the risk is oversizing and thus loss of efficiency.

A system based on 3MXM52N8 would work monovalently without difficulties. A system based on 3MXM40N8 would work bivalently (parallel operation with the convectors below a certain temperature).

- 3MXM52N9 can modulate its absorbed electrical power from 0.30kW to 2.38kW, implying a minimum load factor of around 12.6%.

- 3MXM40N9 can modulate its absorbed electrical power from 0.30kW to 1.75kW, implying a minimum load factor of around 17%.

At a deltaT of 10°C:

- 3MXM40N9 is solicited at 17%.

- 3MXM52N9 is solicited at 12%.

Both units, therefore, operate at their minimum load factor for a deltaT of 10°C. Both units would undergo the same start/stop cycles.

Notably, these two units share the same compressor and heat exchanger, differing in the ventilation system. The MXM52N9 would probably be less efficient due to the inappropriate ventilation system most of the time. However, adopting this unit will not cause premature wear compared to the 3MXM40N9.

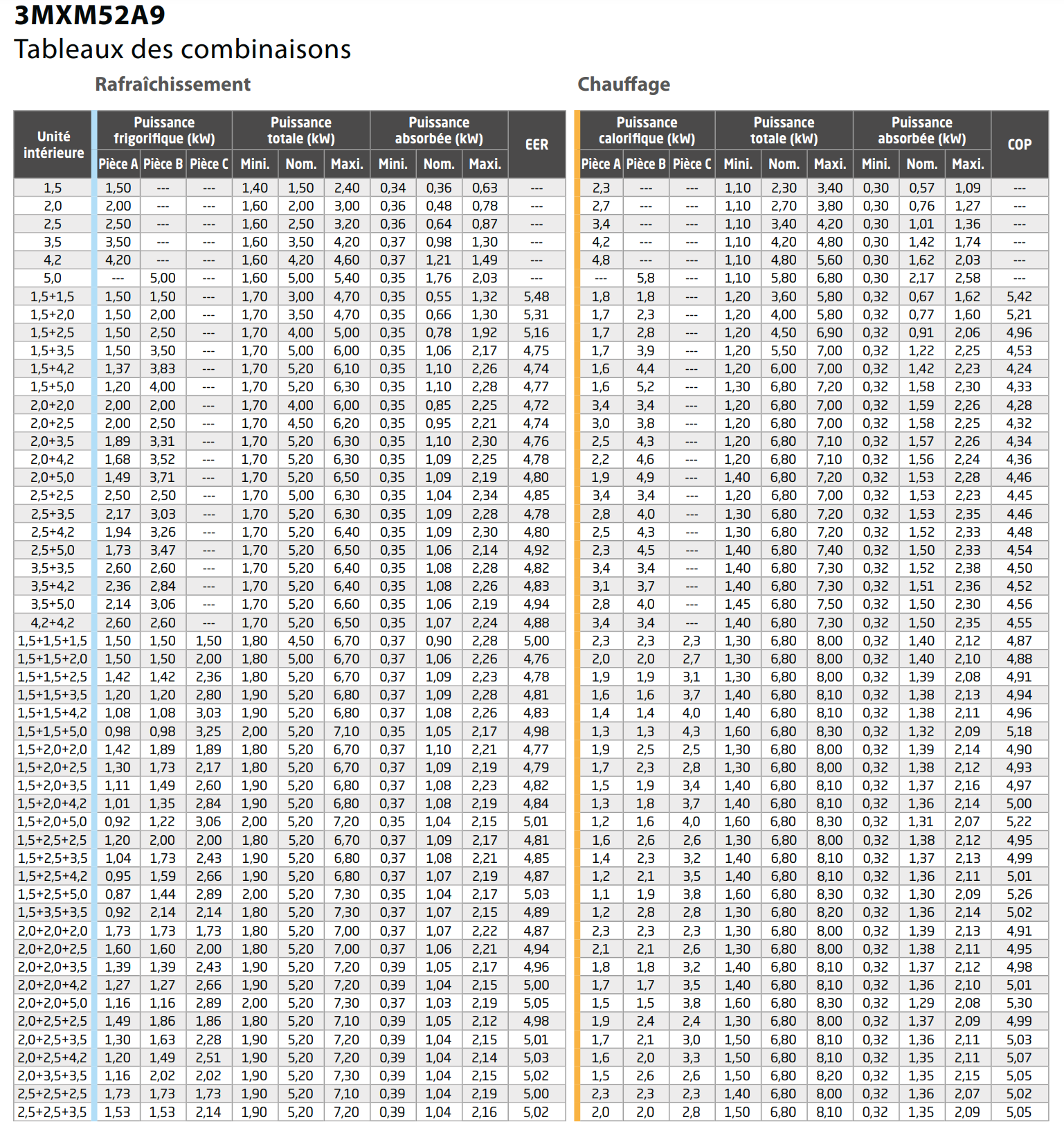

Internal units sizing

- 1x FTXA25 on the ground floor

- 1x FTXA35 upstairs

- 1x FTXA25 in the attic

This roughly matches the existing convector installation for the ground floor and upstairs. The unit in the attic is for cooling only and does not need to heat.

A combined system of 3MXM40N8 + 25 + 35 at +7°C outside and +20°C inside (deltaT 13°) provides the following heating powers:

- 1.92kW on the 25

- 2.68kW on the 35

Excluding the attic's 25 cassette (not used for heating), we simulate a simple 25 + 35 setup, delivering 4.6kW from the two cassettes, matching the power of the 3MXM40N8 at +7°C.

This confirms that the cassettes are limited by the external unit. If the unit can produce thermal power, the cassettes can utilize it. The cassettes themselves do not induce temperature variability.

- 3MXM52N9 (25+35): Heating COP of 4.46, Cooling COP of 4.78.

- 3MXM40N9 (25+35): Heating and cooling COP of 4.88.

A heating COP >= 5.3 with 3MXM40N9 (all cassettes). A heating COP >= 5 with 3MXM52N9 (all cassettes).

Tables show a trend towards a better COP when using the maximum number of cassettes simultaneously rather than distributing energy over one or two.

The color code for the 25A and 35A columns aligns with the currently installed convector power (green = same power, teal = higher, red = lower).

Where the 25A would be installed (ground floor), there is 1x 1500W: 1.5kW. Where the 35A would be installed (upstairs), there are 2x 1500W: 3kW.

Since these two volumes are adjoining, the convective heat contribution from the 25A spreads into the volume heated by the 35A. A deficiency in the 35A can potentially be compensated by the 25A within certain limits.

With 3MXM40N8, the ground floor is slightly over-dimensioned. At 0°C, there is a 300W surplus capacity compared to the existing setup. This excess disappears at -5°C. However, the upstairs is under-dimensioned. At 0°C, there is a 500W deficiency, increasing to 800W at -5°C.

If we consider -2°C as the bivalence limit, the ground floor + upstairs can produce 4kW, which is 500W less than the installed power. However, we know this installed power has covered the last 7 winters without difficulties and is probably over-dimensioned.

Daikin systems can prioritize one cassette. It is likely possible that the 35 in priority mode changes the distribution from 1.8kW + 2.5kW to 1.5kW + 2.8kW, based on actual needs.

With 3MXM52N8, everything is over-dimensioned. The system would be very comfortable in monovalent mode far beyond the minimum climatic conditions encountered and likely to be encountered.

This last table illustrates the thermal capacities of cassette pairs with the 3MXM40N8 unit. We can observe the 25+35, 20+35, and 15+35 pairs to see the possible power distribution.

Finally, note that the installation of the external unit is done under a shelter closed on two sides, with an air flow somewhat restricted compared to full outdoor exposure. This has two effects:

- Reducing the temperature around the unit, where the double-flow ventilation system intake is located.

- Reducing the thermal efficiency of the heat pump.

Safety Margins

Consider the following safety margins:

- +10% for initial consumption extrapolation inaccuracies.

- +10% for doubts about the cassettes' ability to distribute heat.

- +5% for imperfect implementation.

- +5% for aging and performance degradation over time.

- +5% due to restricted airflow around the external unit.

- +5% for variability in the volume to be heated (depending on set temperatures, open doors, etc.).

With a 40% margin, there are few doubts about the system's ability to meet heating needs at a given temperature.

- The 3MXM40N8-based system has a ~40% margin at -2°C.

- The 3MXM52N8-based system has a ~40% margin at -7°C.

This confirms the capability of a solution based on:

- 3MXM40N8 in bivalent mode down to -2°C in the worst-case scenario.

- 3MXM52N8 in monovalent mode regardless of temperature.

Energy Efficiency

Is the 3MXM40N8 bivalent system more energy-efficient than the 3MXM52N8 monovalent system?

Calculation is impossible without:

- The COP of each unit at various deltaT° (data unavailable).

- The average hourly temperature data for all winter days over 10 years (difficult to find).

Refrigirant lines and height differences

- Group-Ground floor: 7.5m length, 2.1m height differential

- Group-First floor: 6.5m length, 5.1m height differential

- Group-Attic: 14m length, 7.85m height differential

Factory charge: 1.8Kg Supplement: 0.02Kg/m beyond 30m.

At a cumulative length of 28m, no supplemental charge is needed.

Cumulative height: 15.05m is pretty much within the 15m maximum tolerated.

Installation

Anything above this line was written before ordering and installing the heatpump. Anything below was written after having the heatpump installed.

We signed with ECO SOLUTION 17 who offered a fair price of 6360.50€ VAT excluded and, reasonnable installation delays of less that 90 days.

The two technicians were cordial and protected our house very well. They tested the system under vacuum for longer than strictly necessary and paid careful attention to avoid having to use lift pumps.

Two small caveats though

- They didn't use torque wrenches, but were open to the idea of buying one at my request. It seems suitable torque wrenches were unavailable at they usual retail shop so they ended up doing without.

- They were not approved by Daikin, which I didn't know at the time.

Retrospective

After having used the heatpump during winter 2023-2024, I can now confirm that I was at most 10% off. With a 1°C outdoor temperature the heatpump ran continously at 500W to maintain the inside temperature. Compared to 2000W with purely joule-effect space heater in the same condition. Considering the difficulty in knowing the pricise COP, the calculations were spot on. My safety margins were therefore mostly unecessary and I could have gone with the smaller 3MXM40 exterior unit.

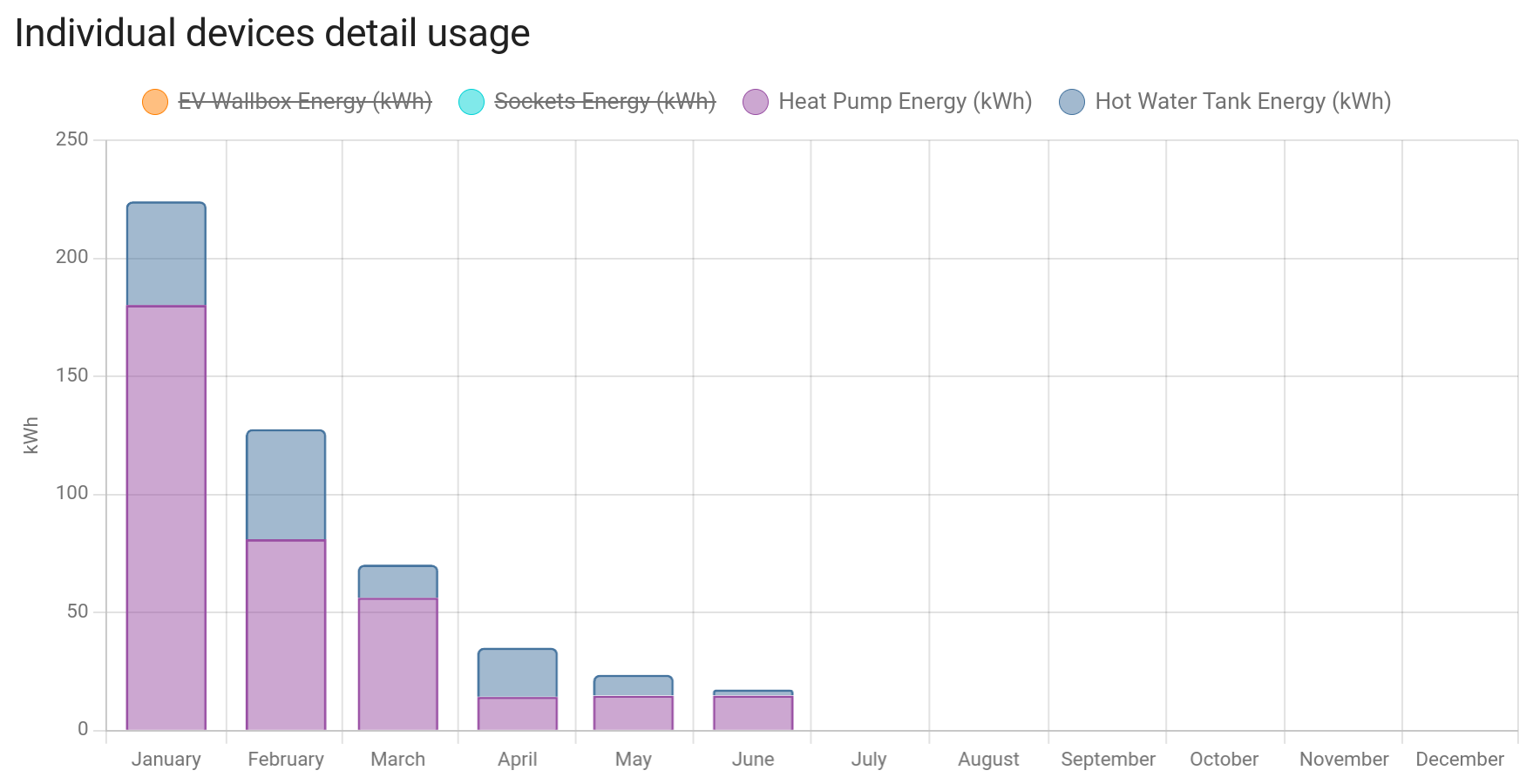

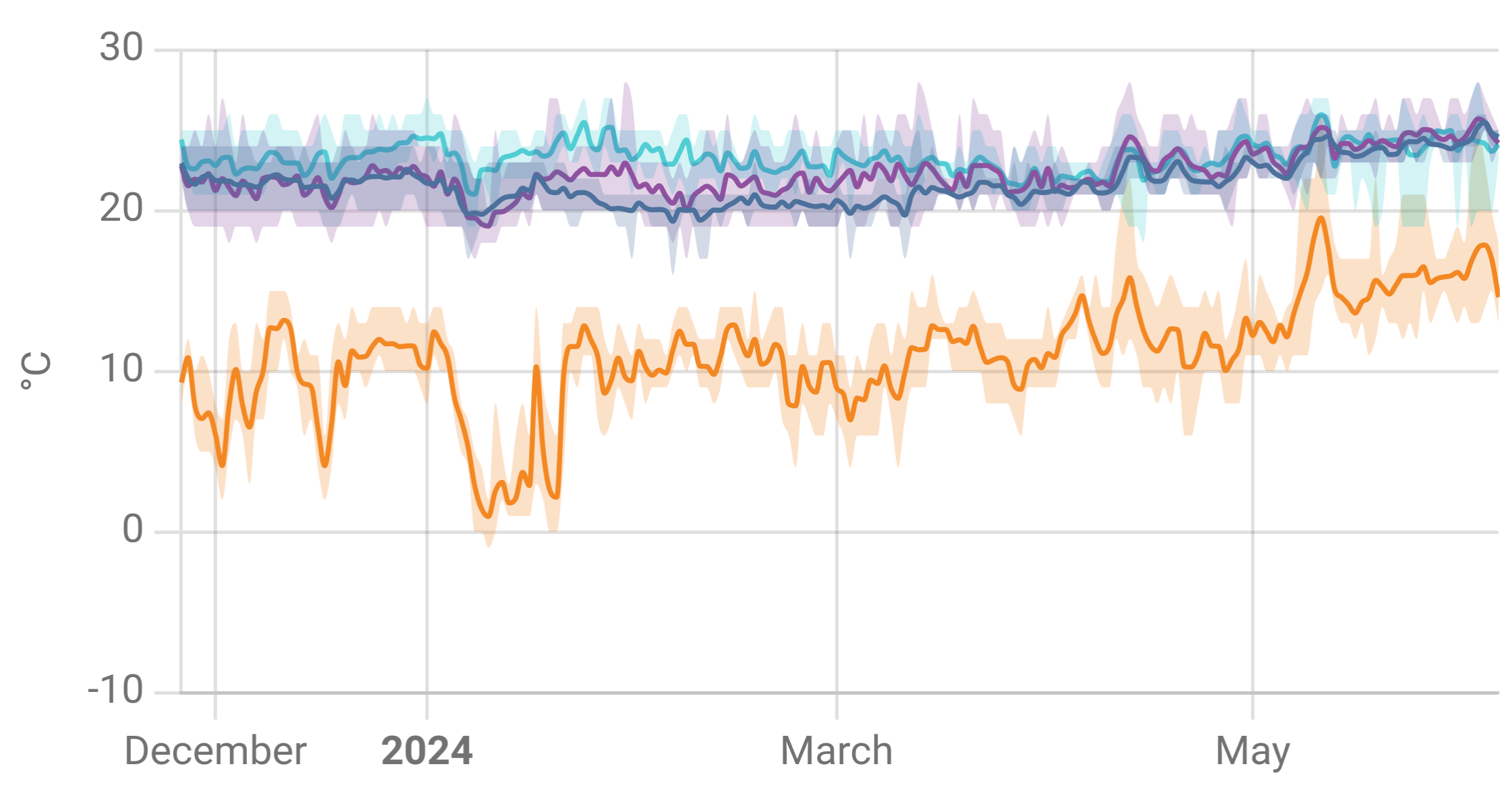

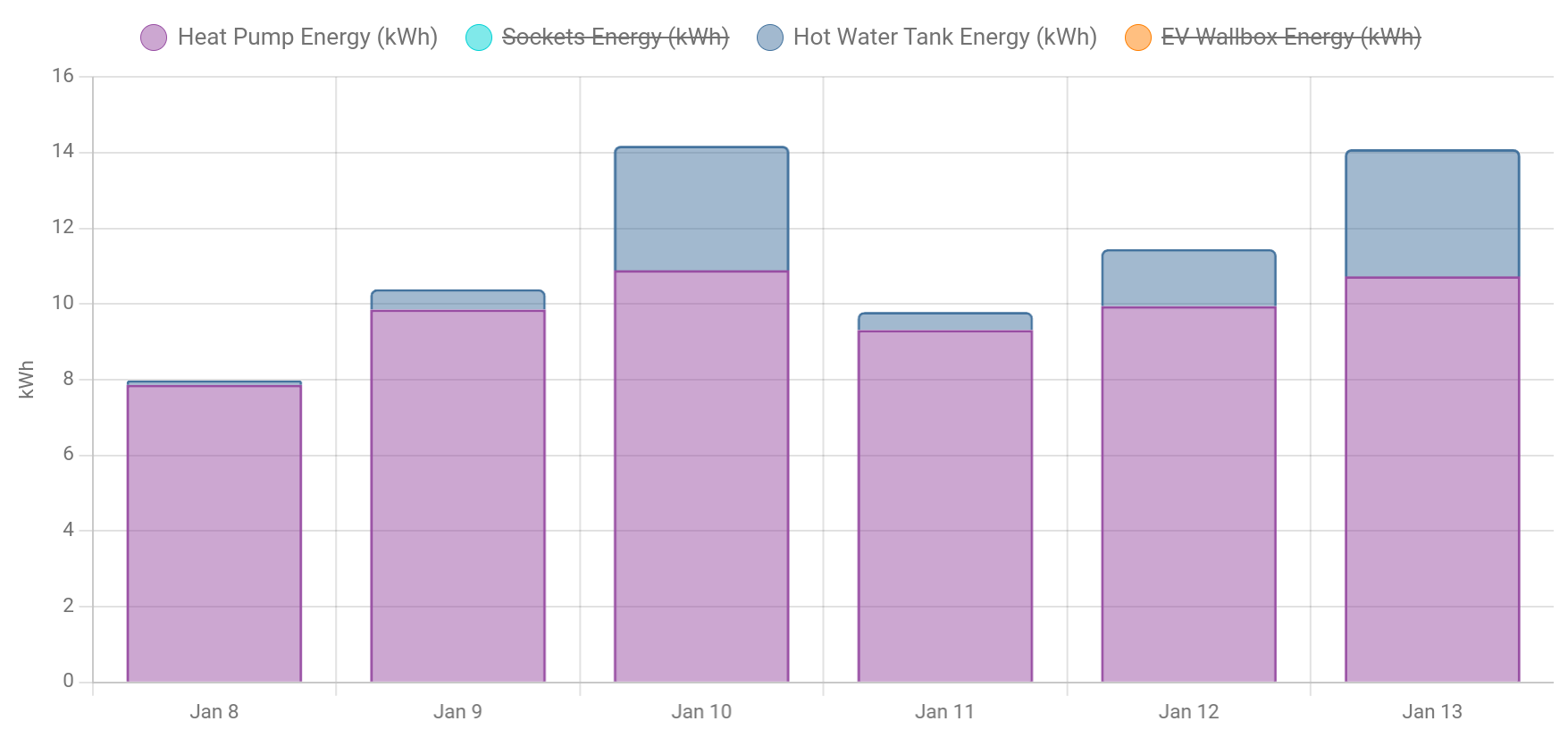

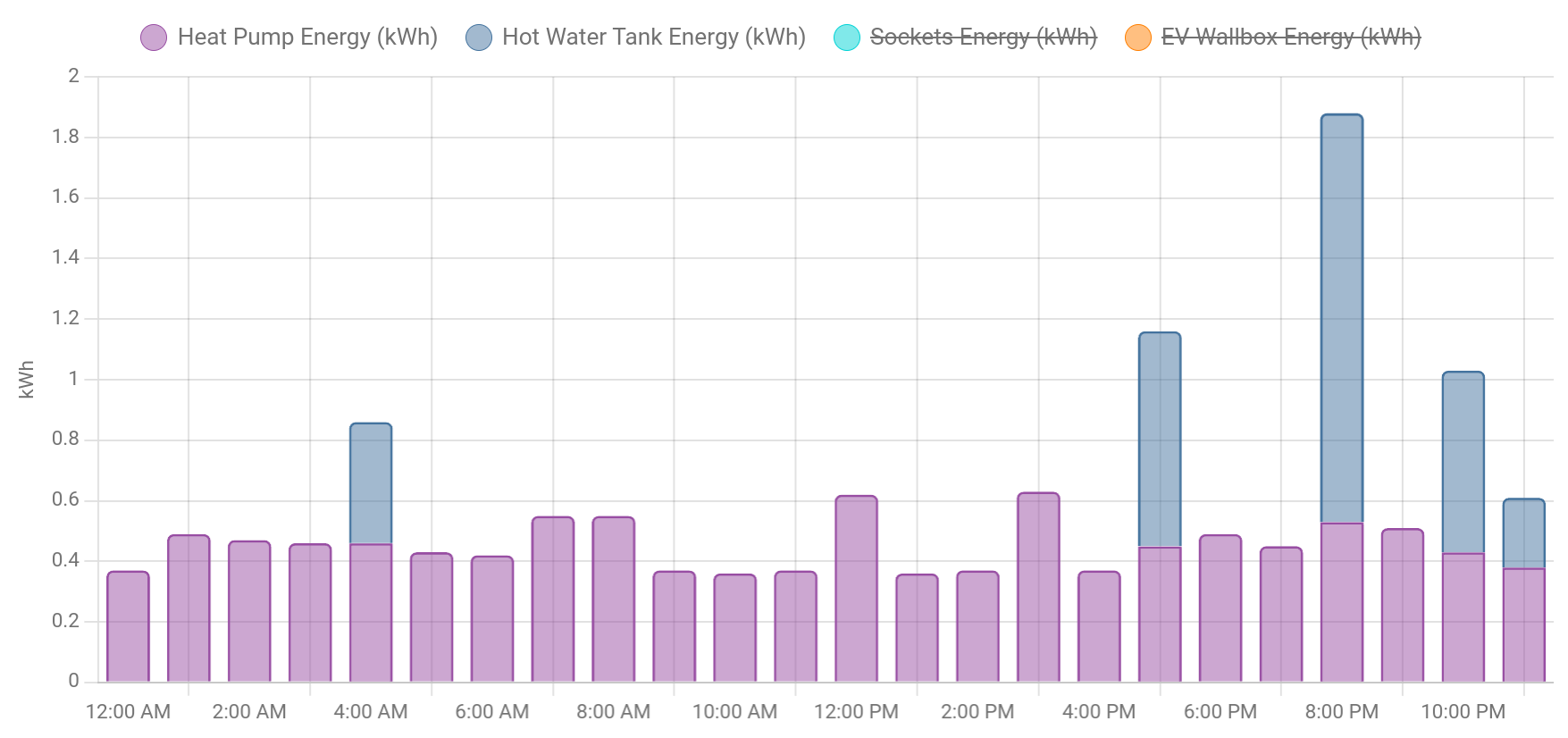

This graph shows the daily energy consumption of the heatpump for the 2023-2024 winter.

This graph shows the temperature for each of the interior units, and the exterior unit for the 2023-2024 winter and 2024 spring. This was an extremely mild winter and I consider only 3 weeks to have been actual "winter".

This graph shows humidity levels measured by each of the interior cassettes, they communicate via wifi directly with Home Assistant.

One of my worries was the partial entrenchement of the exterior unit, in heating mode the temperature around the outdoor unit is only lowered by 1°C in winter. In summer, on the other hand, it can rise by 3 to 5°.

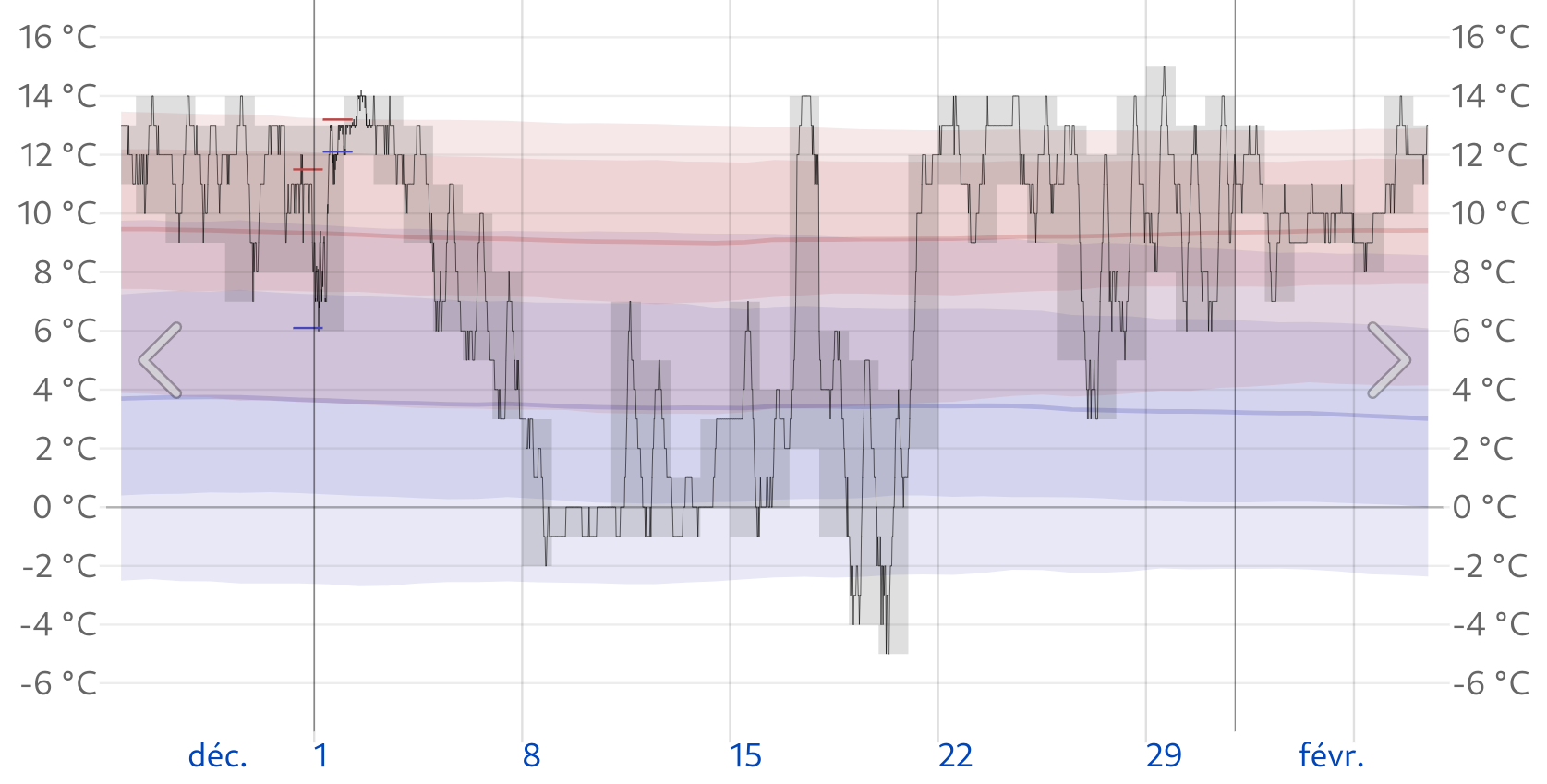

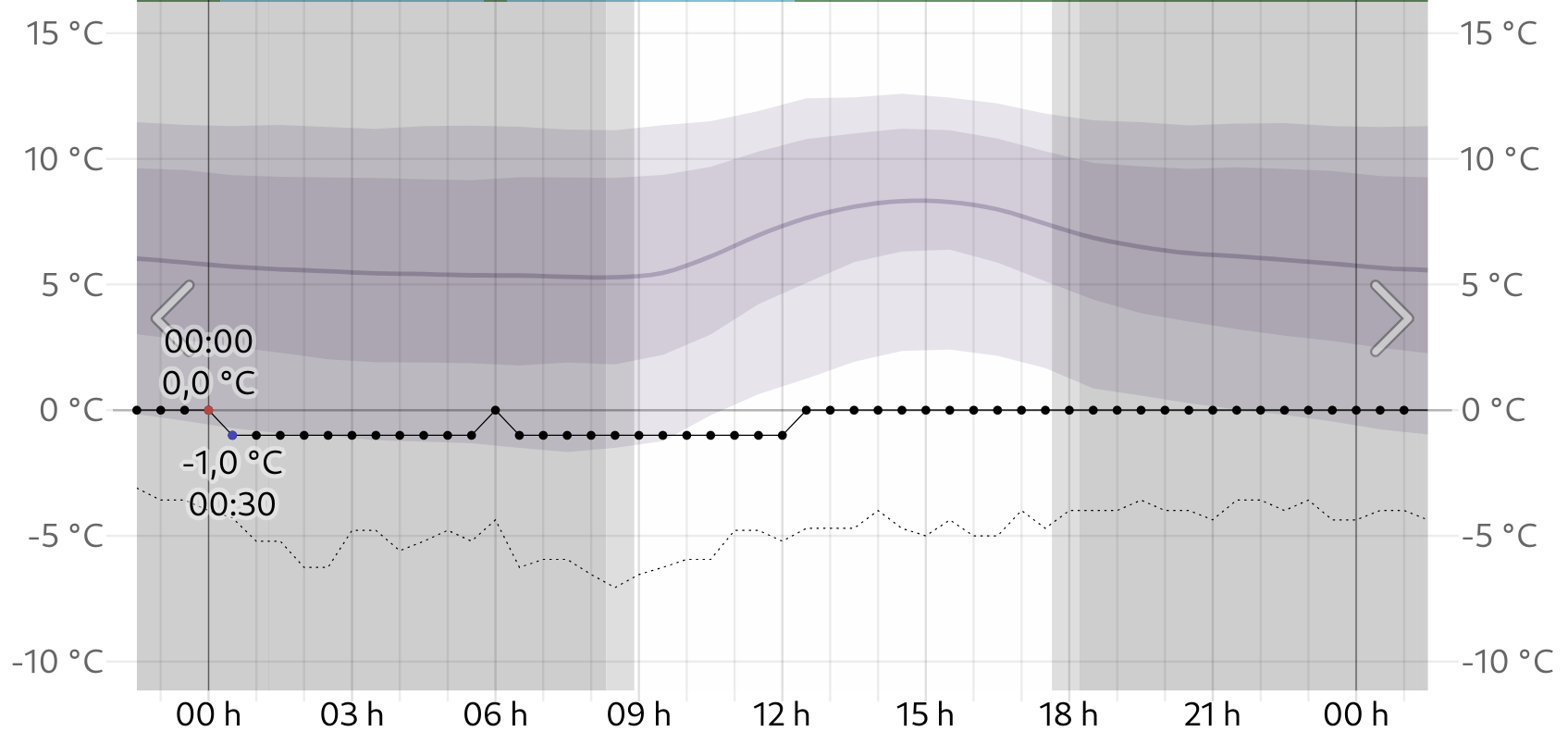

Coldest week of winter 2023-2024

Coldest day of winter 2023-2024

Most of its time was spent around 400W (average of 460W on 24 hours).

First half of 2024